imagine

What Can The Perfect

Membrane Filter Do?

50% decreased energy usage

Reduced pre-treatment & chemicals

Handles higher feed solids concentrations

Higher flux rates

WELCOME TO THE NEW MOVEMENT IN MEMBRANE FILTRATION

Corncob, Inc.'s advanced membrane filtration system, CORNCOB II (CCII), is earmarked to revolutionize the water industry and industrial sector, changing how water is filtered, cleaned and processed for years to come.

Since their inception, conventional membrane technology has employed pressure to drive water through the membrane, and cross flow filtration to limit surface plugging. Narrow flow channels enhance the membrane surface density.

The Corncob system has turned the table on conventional configurations. Very high cross flow scrubbing velocity is obtained with disc rotation at over 50% reduction in energy. High surface density is still achieved with much larger flow spacing, allowing larger feed solids and higher concentrations with zero plugging.

JOIN THE WATER RECLAMATION MOVEMENT

Supplying Matchless Solutions Across the Board

From Increasing Capacities to Reducing Operational Costs, Corncob II is the Clear Choice.

- Pollution Abatement

- Product Recovery

- Water Reuse / Reclamation

- System Expansions / Retrofits

- Emergency Standby Capacity

- Regulatory Compliance

- Relief for Scarce Water Sources

- Reduced Daily Operating Expenses

CORNCOB II INNOVATION

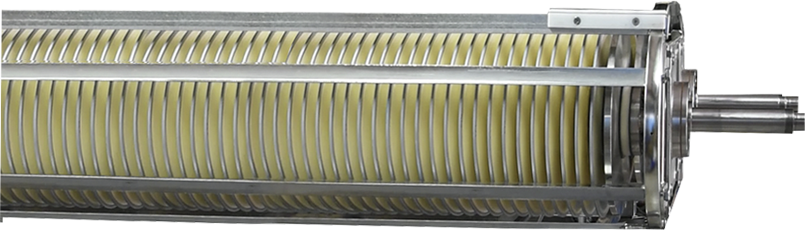

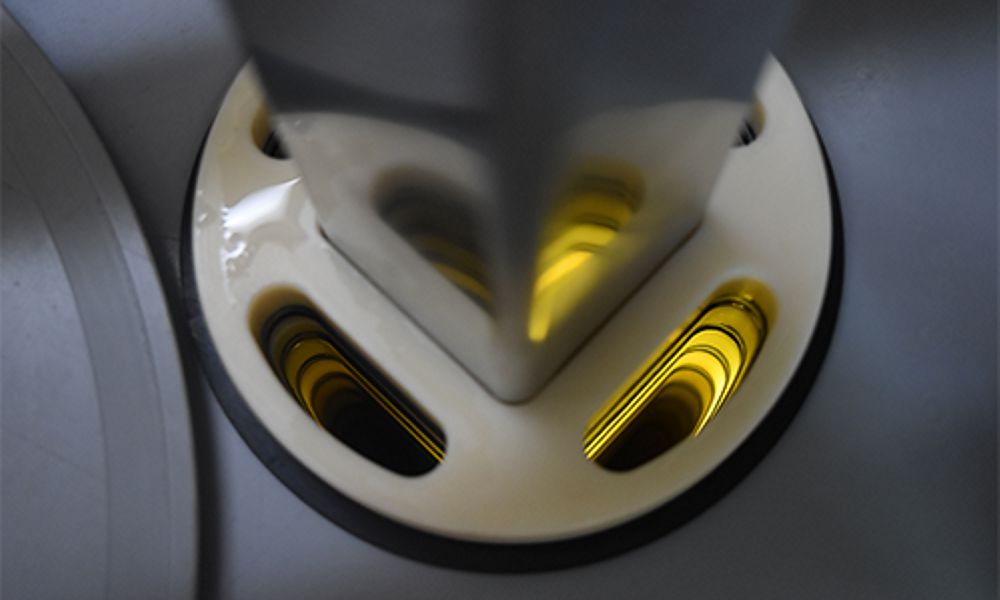

DYNAMIC MEMBRANES

Flat sheet membranes are attached and sealed to a thin, circular plastic disc with underlying plastic mesh permeate carrier. Membranes are applied to each side of the disc.

Discs are arrayed along a supporting shaft with spacing sized to allow for solids access and adjacent disc overlaps into the gaps. Adjacent shafts with discs are rotated to achieve high cross flow velocities between overlapping discs.

- Micro, Ultra, Nano and RO Pore Sizes

- Discs vary in size from 1 foot to 3 feet in diameter

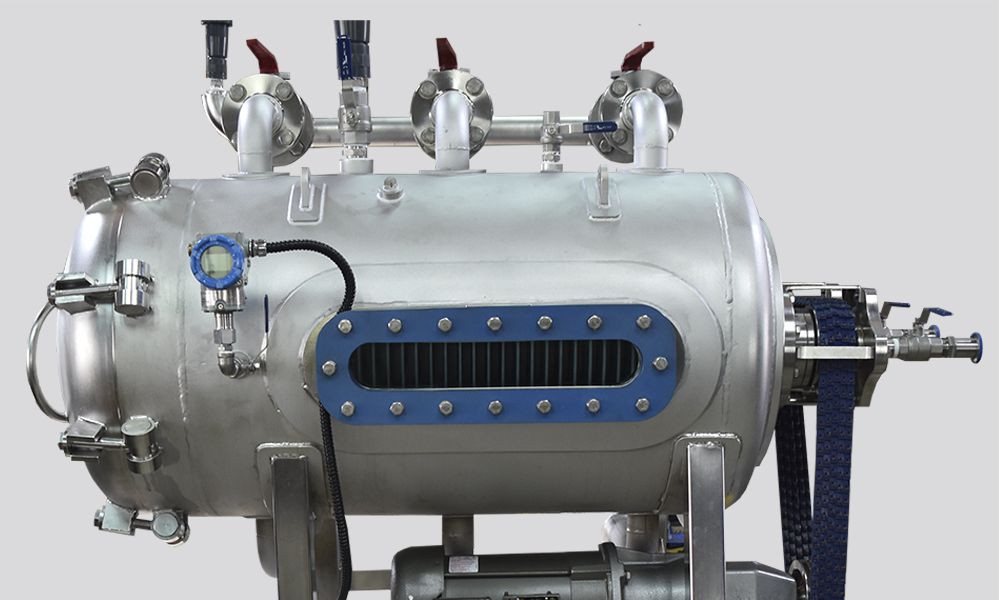

SERVICE MODULE

Pre-fabricated skid mounted process module is engineered for end user simplicity. All feed, discharge, electrical connections are brought to a convenient location for easy commissioning.

- Fully Automatic Plug & Play

- Simple permeate testing during operation

- Built-in Human Machine Interface (HMI)

- System Control from Touch Screen Control Panel or Wireless Tablet

- Skids can be easily scaled to support large applications

PRESSURE HOUSING

Fully enclosed, single unit that encases membrane cartridge. Feed water enters the housing through one of the multiple inlet nozzles, passing through the rotating membranes creating high transmembrane pressure. Permeate is released through one of multiple outlet nozzles.

- Pressure Range from 10 - 600psi

- Multiple feed inlets give operator full control over flow patterns

- Wide variation of pre-fabricated sizes

- Multiple built-in safe-guards for over pressurization

- Fully Enclosed, Single Unit

APPLICATIONS

Potential applications include:

- Landfill Leachate

- Municipal Sewage

- Frack Flowback

- Fiber Processing

- Industrial Laundry

- Slaughterhouses

- Breweries, Wineries

- Campgrounds

- Dairy Processing, Cow Manure

- Shrimp Farms

- Bean Processors, Raisin Processors